Thanks to 3D printing on hydrogels, scientists have found a novel way to produce metals and ceramics that are much stronger than those previously manufactured.

Why the first metal 3D printing in the ISS is revolutionising the future of space exploration.

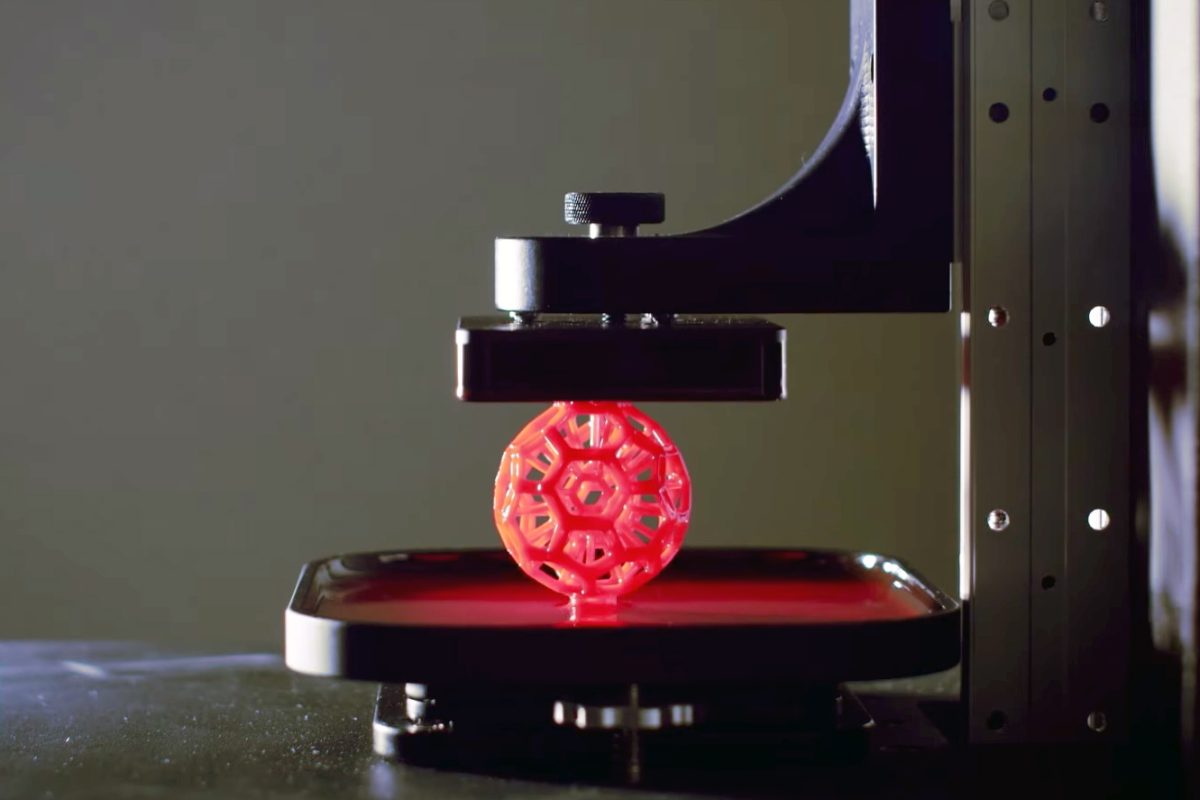

A revolution in the field. In Switzerland, researchers at the Swiss Federal Institute of Technology in Lausanne (EPFL) have developed a new 3D printing method capable of producing metals and ceramics that are much stronger and denser than those manufactured by conventional machines. Their technique uses hydrogels as the initial substrate, resulting in objects that are less porous and less prone to deformation.

Traditional 3D printing methods, such as tank photopolymerisation, work by solidifying a light-sensitive resin layer by layer to form an object. However, this process only works with reactive polymers. Furthermore, the result is often disappointing, leading to fragile or even deformed parts.

‘These materials tend to be spongy, which significantly reduces their strength, and the parts undergo excessive shrinkage as they transition from liquid to solid, which tends to cause deformation,’ explained Daryl Yee, head of EPFL’s Alchemy Lab, to SciTech Daily on Monday 13 October.

A ‘new paradigm’

To overcome the durability problem, scientists first print a hydrogel skeleton, which they then impregnate with metal salts. The chemical reaction then transforms the salts into metal nanoparticles that are distributed throughout the gel and the entire structure. It should be noted that to increase the metal concentration, the process can be repeated several times. The whole thing is then heated to give it a solid form. At the end of this stage, all that remains is a dense metal or ceramic structure, faithful to its initial form.

‘Our work not only enables the production of high-quality metals and ceramics using an accessible and inexpensive 3D printing process, but also highlights a new paradigm in additive manufacturing, where the choice of materials is made after 3D printing, rather than before,’ summarises Daryl Yee.

A robot to automate and speed up the process

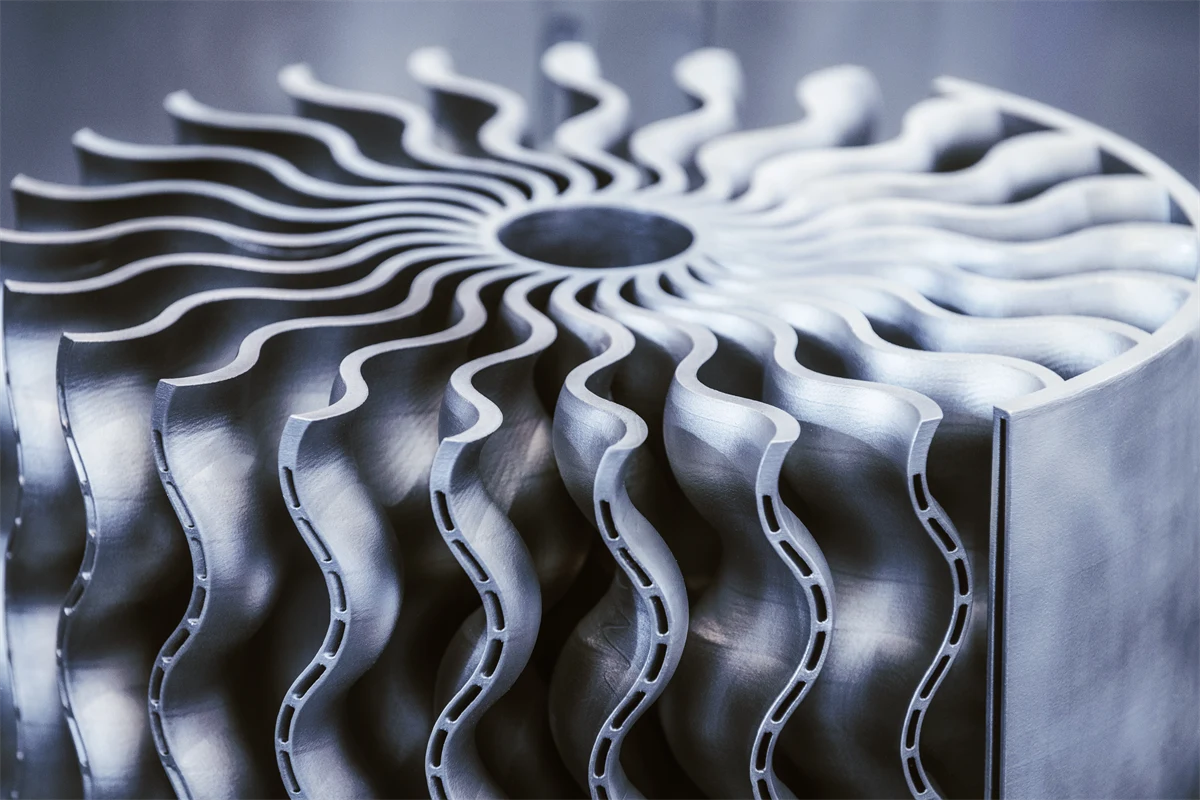

To test their process, the team manufactured complex three-dimensional structures, called gyroids, from iron, silver and copper. When subjected to strength tests, these gyroids proved that they could withstand up to twenty times more pressure than parts obtained using traditional methods, while reducing the risk of deformation to 20% compared to 60-90% previously, says PhD student Yiming Ji, the lead author of the study.

To save even more time and facilitate the adoption of this technique in industry, researchers are also working on automating these various steps with a robot. The innovation could soon be reused in other sectors, such as biomedicine, energy and information technology, to manufacture new equipment or components.